When we talk about systems, even domestic ones, we often hear about

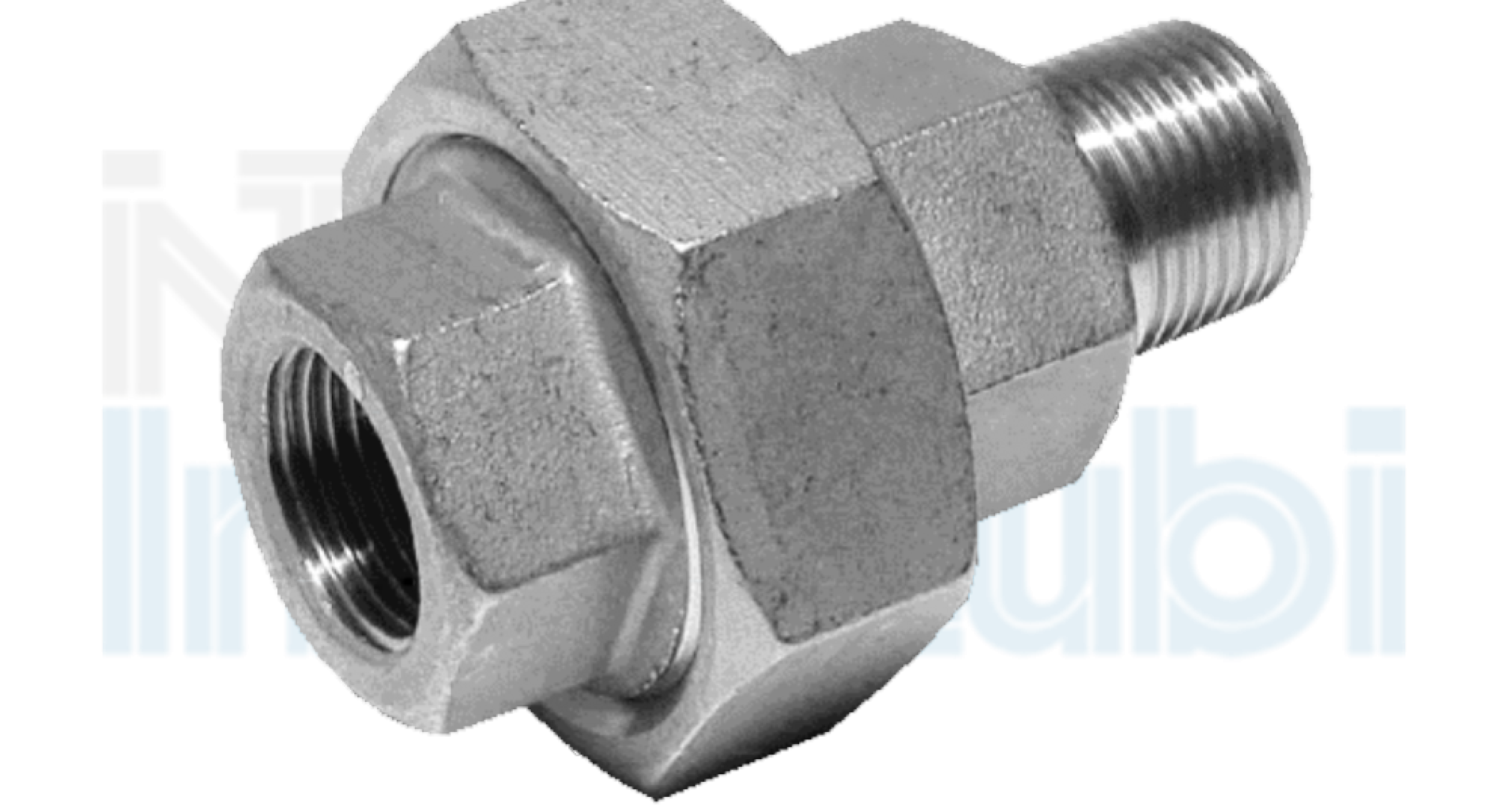

stainless steel unions. But what are they in practice? The unions, as also reported by the dictionary, are hermetic and threaded mouths which act as a connection between pipes.

The definition highlights some fundamental characteristics of these components:

- mouths: they are found, therefore, in the connection areas of the pipes;

- connection: act as elements of continuity between one pipe and another;

- hermetic: they must guarantee a perfect seal without causing leaks, even minimal ones;

- threaded: the connection with the pipes takes place through the use of threaded connections.

Now let's get into the specifics of these words trying to better understand the meaning of these components in plumbing systems, trying to highlight their importance.

The use of stainless steel for the unions

Stainless steel is the most common material for making fittings and components for the hydraulic sector. The alloy, in addition to the classic iron and carbon of steel, has considerable percentages of Chromium (Cr) and Nickel (Ni) which are essential for giving it its main properties. Usually the most used for these applications are austenitic stainless steels, with a face-centered cubic lattice. Among the best features are:

- corrosion resistance: an essential feature for any product that has to work in particularly aggressive environments that can partially or totally compromise its characteristics

- the mechanical resistance characteristic of the steel family;

- resistance to viscous creep;

- ease of processing: important property for products that must be manufactured on a large scale;

- absence of ductile-brittle transition: they cover a very wide range of application temperatures without encountering problems of any kind from the point of view of fragility.

Although these represent only some of the main characteristics, they clearly highlight the importance of this material for the unions.

Threading: Why Yes?

The use of threading as a method of connecting the unions with the pipes represents a need that has developed for application reasons. Although welding probably guarantees a tighter and more continuous connection, it does not allow one or the other component to be replaced which presents problems during the maintenance phase. Furthermore, welding requires skilled operators and equipment that may not always be available or able to be used. In fact, the systems on which the unions are mounted are many and varied in nature and accessibility is not always adequate.

The unions, hermetic components

Another characteristic of the unions, as mentioned, is the need for a hermetic seal. Leaks, even minimal, can cause malfunctions or inconveniences that can compromise the system or the buildings that serve as users.