In the world of hydraulic fittings there are numerous types of components that are present within any system: among these we cannot forget the

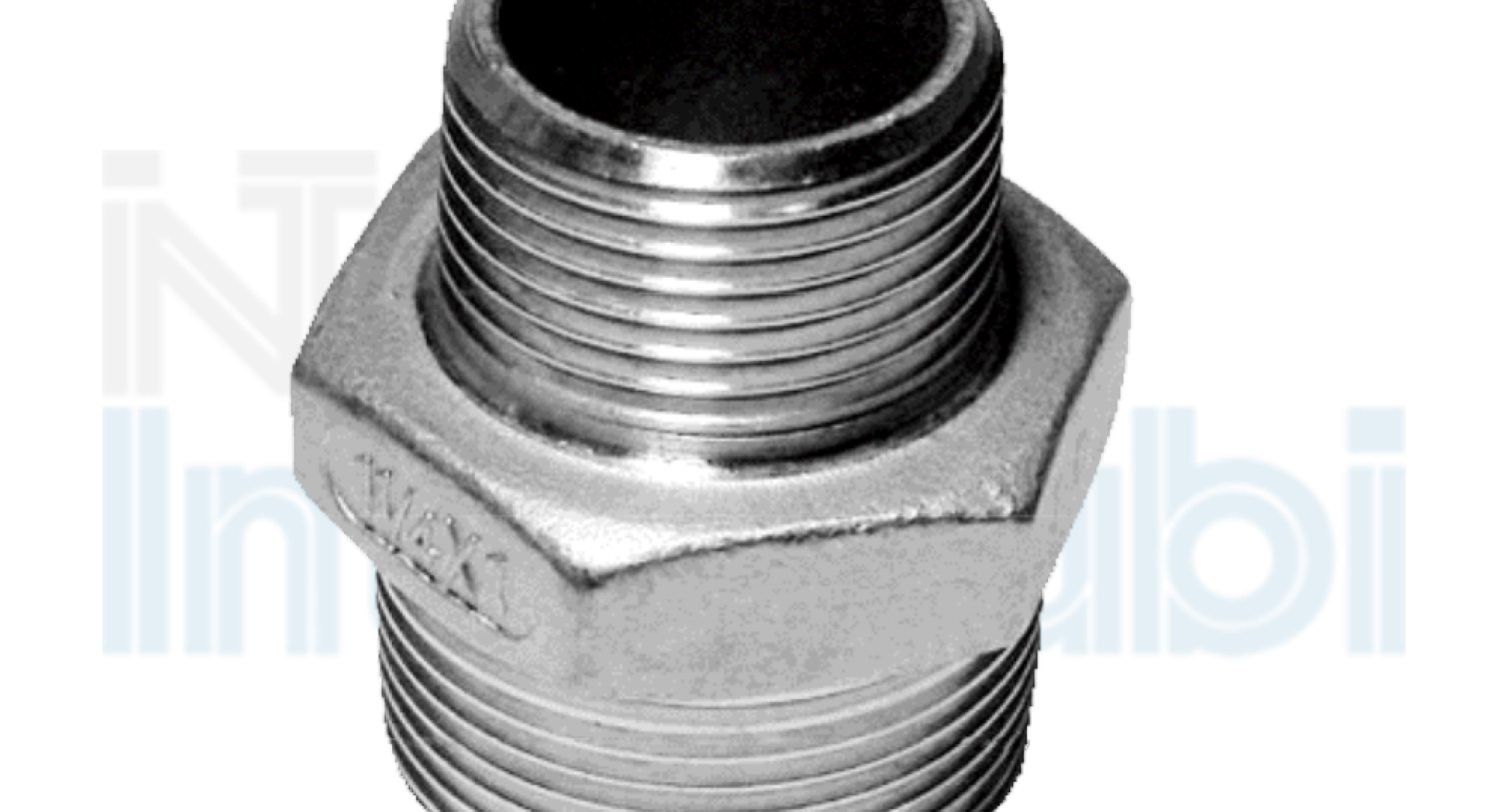

nipples. These elements are tubular fittings with threaded ends that are used to connect pipes to each other, even with significantly different diameters.

The main characteristics of the nipples

Despite being components characterized by a remarkable constructive and geometric simplicity, they have fundamental properties both for the choice and for the installation:

- Typology: there are, in fact, nipples characterized by the same inlet and outlet diameters but also with different diameters (in this case they are "reducing nipples");

- Nipple diameters;

- Threads: usually of the GAS type, widely used in the world of hydraulic fittings;

- Nut: it is the central hexagonal element that is used for fastening in operation and is essential for the choice of the wrench.

The materials used for the construction of the nipples

The materials usually used to construct the nipples must respond to the constructive characteristics of these components, namely the mechanical strength and resistance to corrosion. In fact, in operation there are efforts, especially cyclical, which can lead to failure and the environment of use can lead to progressive degradation and loss of functionality over time, up to breakage and malfunction.

For these reasons, the most used material is austenitic stainless steel which has suitable mechanical and anticorrosive requirements (thanks to the large presence of chromium and nickel in the chemical composition). Furthermore, it does not present a clear ductile-brittle transition due to temperature and this leads to the possible use of these components even in particularly demanding situations.

Despite this, there are nipples made of many materials based on the specific applications that concern them. In fact, they can be made of brass, carbon steel and high-performance polymeric material.

The production process of nipples

There are various production methods for making nipples but among the main ones there is undoubtedly the plastic deformation which allows to obtain morphologically suitable products to be used in operation. Welding processes are also common (for “weld nipples”) and tapping and turning operations allow the creation of connection threads. In addition, there are also nipples made using the casting technique.

The fundamental aspect, as for all the components that are used in the construction of systems, is to have a certified supply chain, to follow specific regulations, to design according to recognized criteria, to make use of the company experience, to train the staff properly, to provide for installations by specialized technicians and maintain the nipples at regular intervals of time.

The use of nipples in the industrial world

Anyone who has ever entered the world of industrial production, both in Italy and in the rest of the world, has certainly found himself in the presence of a considerable use of nipples for connecting hydraulic systems. In fact, the main feature, that is simplicity, makes these components versatile and usable in various contexts, favoring their installation, increasing efficiency and reducing risks.

Some examples of application in the industrial field can be given.

- Machine tools: presenting a series of circuits for water and hydraulic management, they require fittings such as the nipple to facilitate the connection and ensure the general functionality of the specific machinery;

- Molds for die-casting and for the molding of plastic materials: they are characterized by hydraulic circuits for the movement of the cylinders and by water circuits which are used to ensure thermoregulation. The connection to the control units requires the use of nipples trying to minimize losses and increase the efficiency of the molds themselves;

- Industrial cooling systems: they allow you to regulate the temperature of machinery, ovens and other equipment which, due to the activity they carry out, can have high temperatures which must necessarily be reduced to avoid problems and damage.

Although these are just some examples of the application fields of the nipple, it follows that its use is varied and central in the production world.

Defects that can lead to non-compliant nipples

In the previous paragraphs, the design, construction and application characteristics of nipples in the world of hydraulic fittings have been introduced. If one of these components is missing, different risks may arise both for the operation of the systems and for the structural stability of the buildings where these systems are located.

The defects that the nipples may present are:

- Presence of cracks: lead to flow losses and pressure losses. They are mainly due to the production process not being carried out correctly combined with operational loads that exceed the resistance characteristics of the materials themselves.

- Not perfect axiality: also in this case the risk is not being able to have an efficient connection available.

- Incorrect threading: by failing to correctly match the involved parts, the risk is of not being able to use the system to carry out its functions. It can be a problem generated especially in the production phase, with parameters and settings of the tapping phases not correctly set.

In addition to these intrinsic problems in the product, different problems may also arise which derive from the design phases. Making incorrect choices can affect the pressure levels involved which may exceed, or be excessively lower than, the limits imposed by the application case.