Flanges are very important components within the world of mechanical engineering, but also in that of hydraulics. In fact,

flanges are edges or protrusions that increase the mechanical strength of a component close to the connection area, stabilizing it.

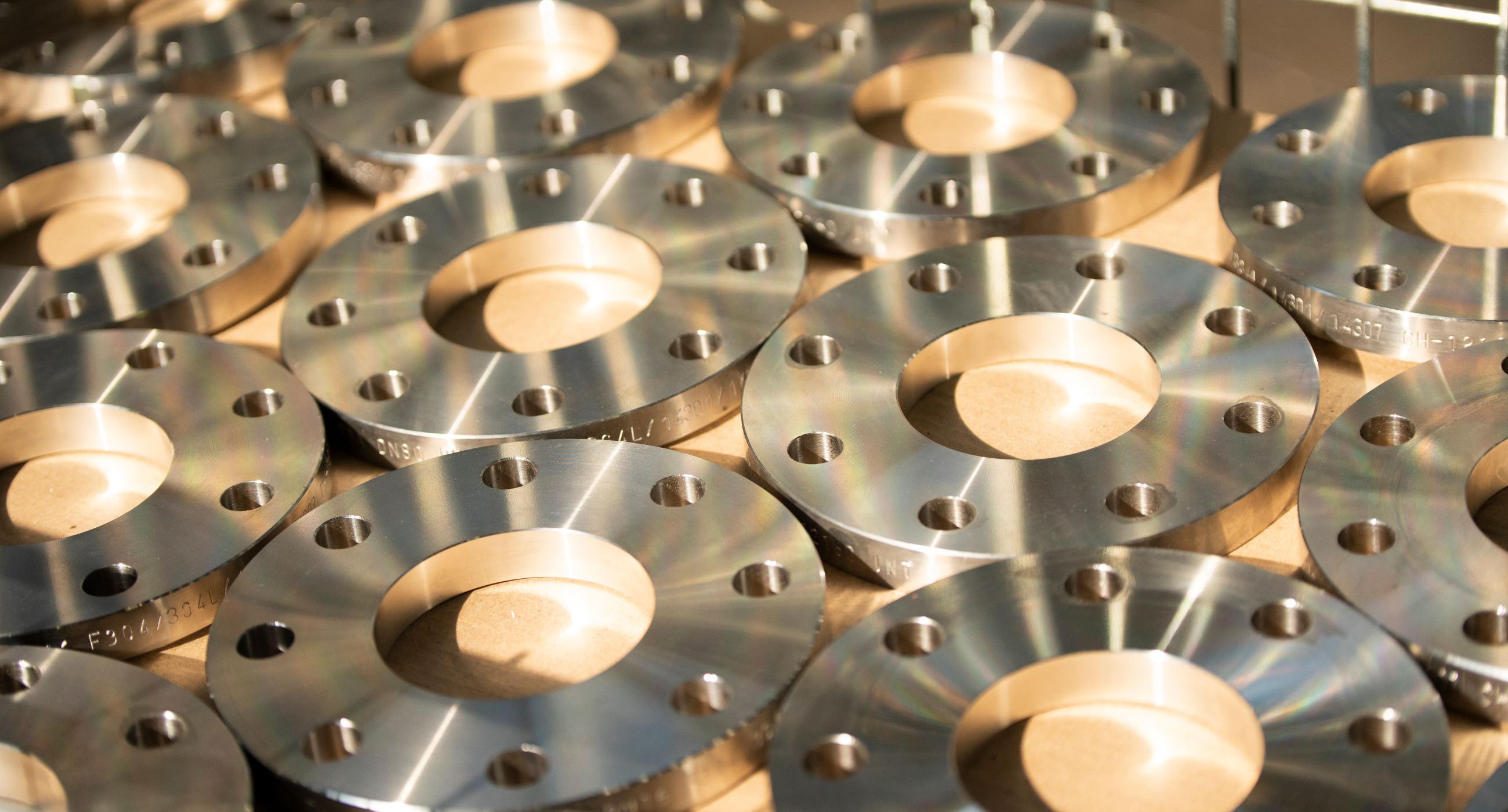

There are various types of flanges on the market, based on the conformation and geometry they present, but also on the construction methodology: although this last distinction is true, most of the flanges are forged and obtained through the process of the same name. Furthermore, another important discriminant is the type of connection made.

The various types of forged flanges

As previously introduced, the flanges are characterized mainly on the basis of morphology:

- Plate flanges: these are the most common and simplest type of flanges;

- Raised face flanges: have a central step that helps in centering;

- Flanges with octagonal section: they have a different profile (octagonal) than the others (round);

- Others: this category includes single and double flanges, both male and female.

The other important distinction, as anticipated, is based on the type of connection:

- To weld: the connection is made through the welding process that can be carried out by lap joint, neck or socket, with different characteristics and advantages;

- Threaded: the connection is made by means of bolting, thus allowing unscrewing and replacement in case of damage;

- With support ring and other types.

It is important to underline that, despite the differences that may occur between one type and another, forged flanges have been standardized for over a century by means of national, continental and world standards and laws on the basis of the nominal pressure that the connection made between can withstand them: this value is not to be understood (as always in the world of design) as an insurmountable limit, but is calculated with appropriate safety factors that allow you to consider any type of inconvenience found during operation due to the construction, implementation and wear of time.

The choice of the manufacturing process for forged flanges

The choice of the forging process for the realization of the flanges derives from two of the most important aspects for any production process: quality and cost. In fact, this process, on the basis of the not excessively complex geometry, allows to produce a large number of components in a short time without compromising with the quality of the product. However, it is clear that without an in-depth study of the type of processing, a large number of rejects can occur. In addition, drilling and other chip removal operations are also required to make the connections.

The steel forging process

As introduced in the previous paragraphs, the forging process is ideal for obtaining steel flanges. The main aspect that characterizes this technology consists in heating the material to a suitable temperature to make the product ductile and malleable, reducing the effort required to modify its geometry.

The main characteristics are:

- Execution using an open mold: contrary to what happens with the classic molding process which requires two half-molds which, when closed, give shape to the product. The design of the mold, in addition to the choice of parameters and the sizing of the press, represents the design core of the process;

- Presence of hydraulic or mechanical presses: they are the fundamental component to impart the appropriate pressure on the material and obtain the required geometry. For this reason, the calculation of the appropriate tonnage and the realization of the plans are central steps of the forging process;

- Refinement of the crystalline grain and direction of the fibers: these metallurgical characteristics allow to have a product with better mechanical characteristics while maintaining good ductility.

It is evident, on the basis of what has been expressed, that the project team plays a a pivotal role in the success of the product. In addition, experience and maintenance allow errors to be minimized by avoiding aesthetic and functional problems of forged flanges.

The combination of forging and hardening heat treatment

As analyzed in detail in the previous paragraphs, the role of forging is central in the production of flanges, regardless of the type and functional characteristics of the latter. In fact, by exploiting the increase in ductility as the temperature increases, it is possible to modify the morphology of the starting component, reducing the required efforts and obtaining mechanical characteristics suitable for subsequent applications.

However, in some cases it is necessary to carry out subsequent heat treatments to improve the resistance characteristics and guarantee excellent characteristics for the final products. In particular, the most widespread treatment is the hardening heat treatment, usually followed by multiple temperings.

What is tempering heat treatment?

The heat treatment of tempering is a widely used industrial process that is used to modify the microstructure of a steel component, such as flanges, and which allows for obtaining certain mechanical characteristics.

The treatment consists of heating a component using selected thermal ramps until reaching a suitable temperature within the austenitic range of the steel. This heating can generally occur with a series of intermediate preheatings aimed at homogenizing the temperature and structure of the component. After an appropriate maintenance, finally, the component is rapidly cooled, not allowing the classic diffusive phenomena of solidification. For this reason, instead of the typical pearlitic structure of steels, a martensitic structure is obtained with a body-centered tetragonal lattice with carbon that is unable to diffuse.

The role of tempering

The tempering heat treatment is generally carried out several times at the end of the tempering process to obtain the final characteristics of the product, which will mean an ideal combination of mechanical resistance and ductility. It is usually carried out by bringing the material below the Ac1 temperature in order to guarantee the restoration of the diffusive phenomena of the carbon that were previously inhibited. It is important to temper the martensite formed because it is excessively fragile and, on the other hand, it is important to guarantee the transformation of all the residual austenite that can have highly negative effects on the mechanical characteristics.

Important precautions in the hardening and tempering process

Forged flanges must be made taking into account some aspects:

- it is important that suitable spokes are present to avoid stress intensification effects;

- drilling, where possible, is best done after hardening because it involves moving the axes and, therefore, requires subsequent recovery operations;

- It is important to check the technical data sheets and CCT curves of the reference steel.